Why Join Us?

We're expanding! If you're passionate about sales and excited to work across diverse industries including Oil & Gas, we want you on our team. We're looking for driven individuals as Key Account Manager to identify new business opportunities and build strong client relationships across Malaysia, Singapore, Indonesia & China.

-

Attractive Pay: Basic + Profit Sharing

-

Perks: Travelling Allowance, Petrol/Toll/Parking Claims, Outstation & Entertainment Claims

-

Fair work Life Balance: Monday to Friday | 🕣 8:30 AM – 5:30 PM, no weekends!

-

Free Parking

-

Medical, Dental & Optical Coverage

-

Rewards: Monthly Top Sales Awards, Incentives & Performance Bonus

-

Extras: Training, Medical Claims, Sports Day & More

-

Growth: Skills development in a supportive, high-energy team environment

What You’ll Do

-

Responsible for the Company’s sales-related activities including identify and developing new business, growth strategies and opportunities in the market and maximize long term profitable volume growth.

-

Identify market trends and demand for better sales and marketing strategies.

-

Monitor competition steps and price campaigns.

-

Analyses the market and determines the sales strategy including a market-specific pricing policy.

-

Provide support and after sales services include problem resolution, expert advice, consultancy and strengthening customer relationship.

-

Works in close collaboration with customer and sales team ensure a smooth order handling process.

-

Identify new products/target customers, customer preferences and action plans to generate product demand.

-

Recommend and implement detailed annual sales operating plans and preparation of sales performance reports for strategic analysis and review on a monthly or quarterly basis.

-

To perform any other ad-hoc assignments as and when required.

What We’re Looking For

-

Who are sensitive with market trend and have own sense for market strategies.

-

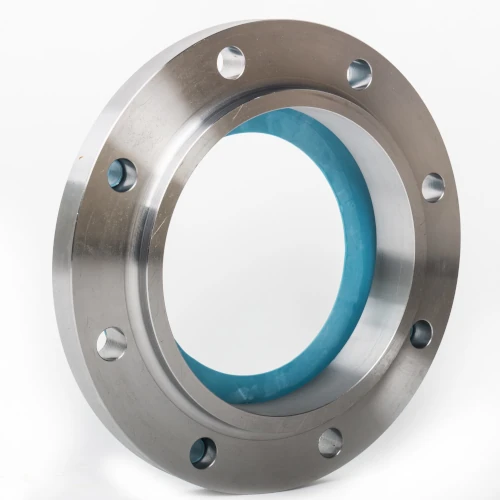

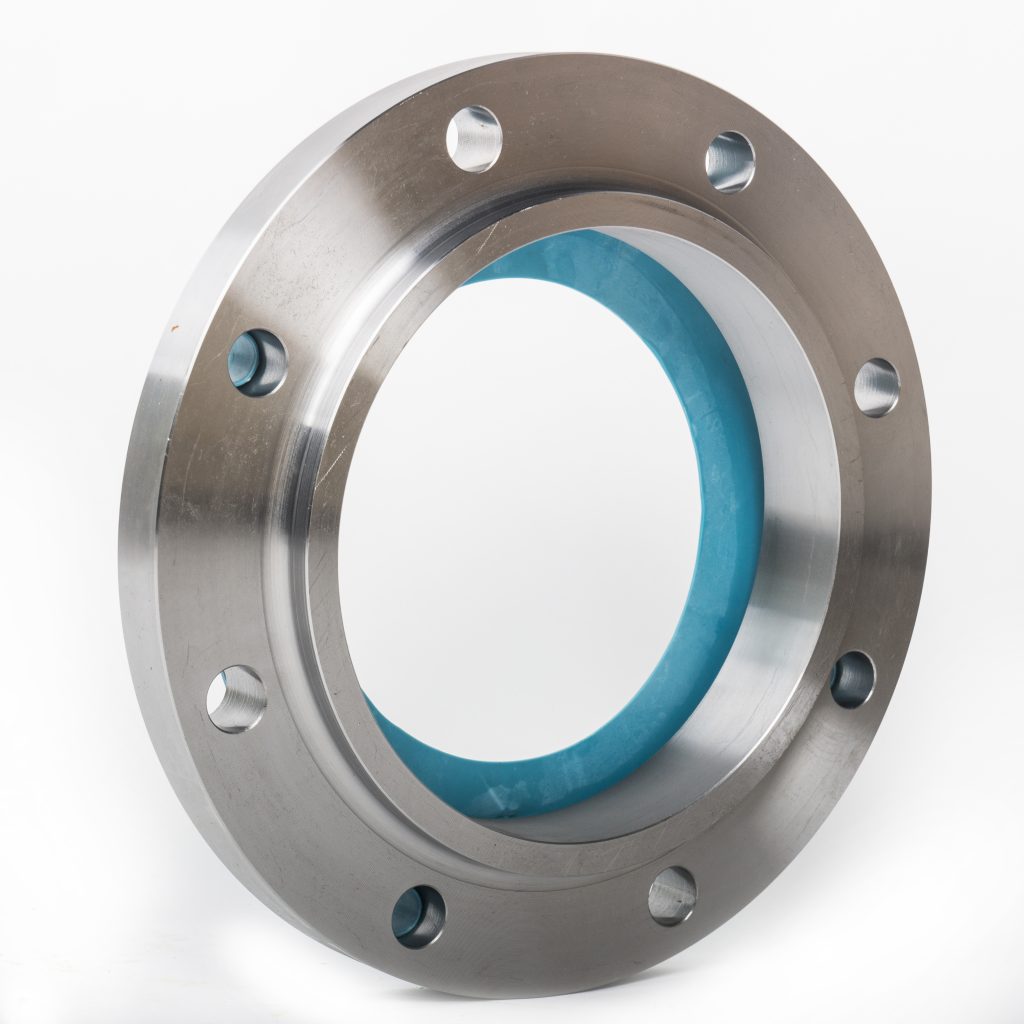

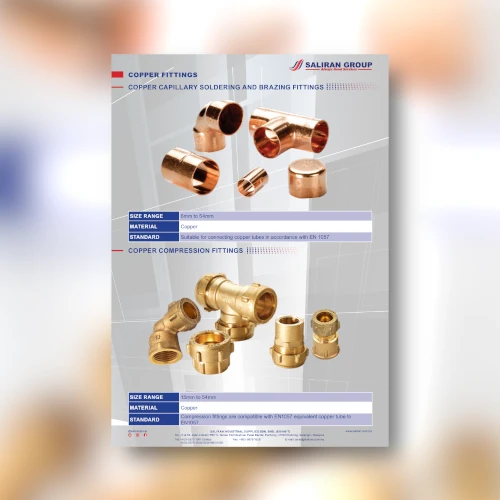

Knowledge for flanges, pipes, valves, fittings are a MUST.

-

You are required to discovered your own customer database.

-

Preferred at least 3 years in the industry mentioned above.

-

Own transport and valid driving license.

-

Fluent in English, Bahasa Malaysia, and Mandarin/Cantonese – Mandarin proficiency is essential as the need to communicate with China clients.

-

Willing to work in Puchong.

Company profile

Saliran Industrial Supplies

Trades & Services

101-1,000 employees

When we see our future, we see NO LIMITS !

SALIRAN Industrial Supplies Sdn Bhd is a conglomerate comprising SALIRAN GROUP BERHAD, which holds the ISO 9001:2015 certification. It serves as the trading and stockholding division, specialising in steel pipes, fittings, and flanges, and is a leading supplier in the oil and gas sector and beyond.

By building strong relationships with international manufacturers and partners, SALIRAN meets industry needs with a complete selection of products and services. The company leverages its resources to develop innovative systems and products, supporting growth in oil and gas, petrochemical, marine, and energy industries.

Perks and benefits

More about us

Company information

Registration No.

201101008001