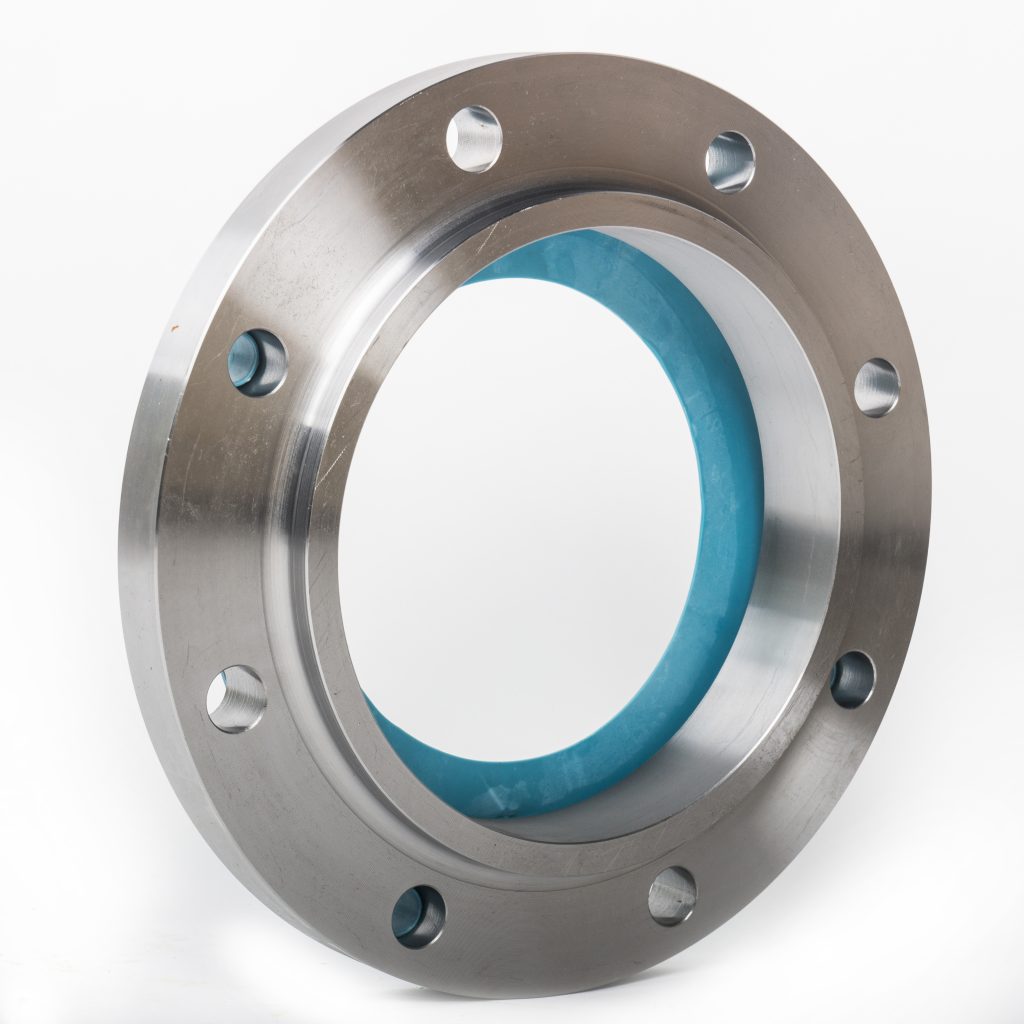

Choosing the right material for slip-on flanges is essential when building or repairing plumbing systems. These flanges are essential parts that join pipes, guarantee stability, and stop leaks. But selecting the appropriate material requires taking into account a number of variables, including general durability, temperature tolerance, and corrosion resistance. We’ll examine the comparative study of several materials used in slip-on flanges in this extensive guide to help you make judgments that are appropriate for your particular application requirements.

Choosing the Right Material for Slip-On Flanges: A Comparative Analysis

A Slip-On Flanges Comparative Analysis evaluates factors like material, pressure ratings, and cost across different brands. It assesses performance, reliability, and ease of installation to determine the most suitable option for specific applications, ensuring optimal functionality and cost-effectiveness in piping systems.

UNDERSTANDING MATERIAL OPTIONS

Carbon Steel Flanges

Slip-on flanges made of carbon steel are well known for their robustness and adaptability for high-pressure applications. They are a popular option in sectors where strength and dependability are crucial because to their durability and affordability. On the other hand, conditions that are more prone to corrosion may call for the use of additional protective coatings or the investigation of substitute materials.

Stainless Steel Flanges

Stainless steel slip-on flanges are well-known for their outstanding resistance to corrosion and are perfect for use in environments with high moisture content, chemicals, or extreme temperatures. While they cost more up front, they last longer and require less maintenance than carbon steel.

Alloy Steel Flanges

Slip-on flanges made of alloy steel combine the qualities of several metals to improve particular attributes. These alloys are appropriate for harsh industrial settings because of their exceptional resistance to pressure, corrosion, and high temperatures.

Duplex Steel Flanges

Slip-on flanges made of duplex steel provide a well-balanced mix of strength and resistance to corrosion. Because of their special makeup, which combines elements of ferritic and austenitic structures, they are durable and appropriate for uses requiring both strength and resistance to adverse environments.

FACTORS INFLUENCING MATERIAL SELECTION

Environment and Operating Condition: Think about the surroundings in which the pipe system functions. Variations in temperature, exposure to corrosive materials, and pressure determine a material’s resistance to corrosion, thermal stability, and overall performance.

Budget and Longevity: Determine how much should be invested initially and how much should be maintained over time. Even though some materials may cost more up front, they may last longer and require less upkeep and replacement over time.

Adherence to Regulations: There are strict guidelines for several businesses about the materials that can be utilized in their operations. To prevent problems with compliance and other risks, make sure the material you choose complies with these standards.

MAKING THE RIGHT DECISION

Every material option for slip-on flanges has benefits and drawbacks of its own. It’s critical to weigh the unique needs of your plumbing system against the characteristics provided by various materials. Making an informed choice can be greatly aided by speaking with professionals in the field and taking historical performance in related applications into account.

Saliran had provide different material that allow you choose the slip-on flange material that best suits your particular requirements by being aware of the characteristics and subtle differences between each option, guaranteeing the lifetime and best performance of your pipe system.

Product Tags

flanges supplier malaysia

Type | Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange, Anchor Flange, Orifice Flange |

Size Range | 1/2" (15mm) - 48" (1200mm) |

Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

Type Available | Raised Face RF, Ring Type Joint RTJ, Flat Face FF, Male & Female M&F, Tongue Groove T&G |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS SCH 10s, SCH 40s, SCH 80s |

Standard | ASME B16.1, ASME B16.5, ASME B16.20, ASME B16.21, ASME B16.24, ASME B16.34, ASME B16.36, ASME B16.42, ASME B16.47 MSS SP-6, MSS SP-9, MSS SP-25, MSS SP-44, MSS SP-53, MSS SP-54, MSS SP-55, MSS SP-75, MSS SP-106 API 605, API 6A, API 6B |

Specification | |

Carbon Steel | ASME/ASTM SA/A105N |

High Yield Carbon Steel | ASTM A694 F42/ 46/ 52/ 60/ 65/ 70 ASTM A707 L1~ L8 |

Low Temp Carbon Steel | ASME/ASTM SA/A350 LF1/ 2/ 3/ 6 |

Chrome Moly | ASME/ASTM SA/A182F2, F5 ,F9, F11, F12, F22, F91 |

Stainless Steel | ASME/ASTM SA/A182F304/304L, 316/316L, 309, 310, 304H, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB564, |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK, Weld Overlay available |

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!