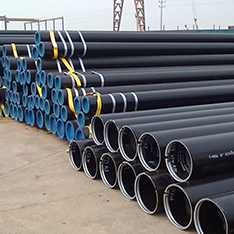

Seamless Pipe

Saliran Group has over 10 years of expertise in the trading and supply of high-quality of carbon steel and stainless steel seamless pipes with numerous happy customers all around the world. We are top supplier of Seamless Pipe Malaysia. We have a large inventory of seamless pipes in sizes that are regarded as industry standards as a seamless pipe supplier in Malaysia. Therefore, we do supply a variety of carbon steel seamless pipes and stainless steel seamless pipes with different standards and specifications to meet your requirements.

What is a Seamless Pipes?

A seamless pipe is a circular steel pipe either in bar or sheet form. A hollow tube is created when a ‘billet’ is cast over a piercing rod. Seamless pipes are well known for their greater feature in tolerating higher pressure compared to other methods. The seamless pipe is used in various industries which includes energy, chemical, oil and gas, pharmaceuticals etc. These Seamless pipes are customized to meet an extensive range of application requirements such as material grades and pressure.

Seamless Pipe | |

Size Range | 1/4" (8mm), 3/8" (10mm), 1/2" (15mm), 3/4" (20mm), 1" (25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28 (700mm)", 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 38" (950mm), 40" (1000mm), 42" (1050mm), 44" (1100mm), 46" (1150mm), 48" (1200mm) |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS, SCH 10s, SCH 40s, SCH 80s |

Standard | ASME/ANSI B36.10, B36.19 |

Specification | |

Carbon Steel | ASME/ASTM SA/A106 Gr A/ Gr B/ Gr C |

High Yield Carbon Steel | API 5L X42/ 46/ 52/ 60/ 65/ 70 - PSL1/ 2 |

Low Temp Carbon Steel | ASME/ASTM SA/A333 Grade 6 |

Chrome Moly | ASME/ASTM SA/A 335 Grade P5/ P11/ P22/ P91 |

Stainless Steel | ASME/ ASTM SA/A312 TP304/304L, 316/316L, 309, 309H, 310S, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | ASME/ASTM SA/A790 UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB163, 168, 424, 443, 575 UNS N02200 (Nickel 200), UNS N02201 (Nickle 201) UNS N04400 (Monel 400), UNS N06600 (Inconel 600) UNS N06601 (Inconel 601), UNS N06625 (Inconel 625) UNS N08810 (Incoloy 800H), UNS N08811 (Incoloy 800HT) |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK available |

We Are Trusted Stainless Steel Seamless Pipe & Carbon Steel Seamless Pipe Supplier in Malaysia

Saliran Group is a leading conglomerate group in Malaysia that is specialized in the trading of a wide range of pipes. To satisfy your application needs, we offer a large selection of welded and seamless stainless steel pipe as well as carbon steel pipe. As a pipes supplier in Malaysia, we keep a large selection of seamless pipes in sizes that are considered industry standards in both stainless steel and carbon steel. Get a price on your steel pipes right away.

Carbon Steel Seamless Pipe

Carbon steel, a combination of iron and steel alloy, is used to make carbon steel pipe, as it is a tough material. According to Carbon Steel Pipe Supplier, this pipe is utilized in a wide range of key industries including construction, ships, distilleries, and agrochemicals equipment due to the strength and capacity to endure stress. Safety and endurance are provided by carbon steel pipe. It makes the good choice for structural applications as it is resilient to stress and unaffected by extreme natural conditions like temperature or pressure. You can get more information about the product from our professional Carbon Steel Pipe Supplier!

Stainless Steel Seamless Pipe

Most often, pipe infrastructure for the transportation of fluids or gases use stainless steel pipe. Stainless steel pipe is constructed from an alloy of steel that includes nickel and chromium, which provides stainless steel its highly corrosive qualities. Because stainless steel pipe doesn’t oxidize, it’s a moderate option that works well in chemical and hot heat resistance. It is because stainless steel pipe is simple to disinfect and clean. The most prevalent methods for producing stainless steel pipe are welding and extrusion. In order to keep the shape after the seams have been welded together, steel must first be formed into a pipe shape. By heating a steel rod and then piercing it through the center to form a pipe, extrusion produces a seamless product.

Seamless Pipe Applications

Seamless pipes are widely used in various industries in Malaysia. In the chemical industry, seamless pipes are employed for processing and transporting corrosive materials. They are also crucial in the pharmaceutical sector, where cleanliness and precision are paramount. Seamless pipes are utilized in high-pressure applications, such as power generation and hydraulic systems. Seamless pipes play an important role in infrastructure projects such as the sewerage industry and water supply systems. With their strength, durability, and ability to withstand extreme conditions, seamless pipes are essential for numerous industrial applications.

Advantages of Seamless Pipes

Seamless pipes offer several advantages that make them a preferred choice in various industries.

- Their seamless construction eliminates the risk of weak points or leaks, ensuring reliable performance.

- Seamless pipes have superior strength, allowing them to withstand high pressure and temperature conditions.

- Their smooth interior surface facilitates efficient fluid flow and minimizes friction loss.

- Seamless pipes offer excellent corrosion resistance, making them suitable for corrosive environments.

- Their preciseness and uniformity of dimension had simplified installation and reduced maintenance requirements.

Most often, pipe infrastructure for the transportation of fluids or gases use stainless steel pipe.