Stainless steel pipe, composed of a nickel and chromium alloy, is commonly utilized in fluid or gas transportation systems due to its corrosion resistance, particularly against oxidation, making it suitable for high-temperature and chemical environments. Typically manufactured through welding or extrusion processes, welded pipes involve shaping steel and welding seams, while extrusion forms seamless products by heating steel rods and piercing them. Although often used interchangeably, “pipe” and “tube” have distinct measurements and purposes: pipes are measured by interior diameter for fluid and gas conveyance, while tubes, measured by outside diameter and wall thickness, are utilized in structural components and part construction.

Types of Stainless Steel Pipe

- Seamless Pipe

A seamless pipe is one that contains no seams or weld joints. Because of the metal, it can withstand high levels of pressure as well as high temperatures. It is also used in numerous oil and gas applications. In addition, it is used in the mechanical and engineering industries. As a result, seamless pipes are extremely versatile, and they are always thoroughly inspected to ensure material quality.

- Welded Pipe

Welded pipes can be found in almost any industry due to their versatility. They outperform in terms of corrosion resistance but not pressure resistance. Welded pipes, on the other hand, are far more cost-effective than most other piping methods. Because of the materials used and their lightweight nature, it may also provide the best value for money.

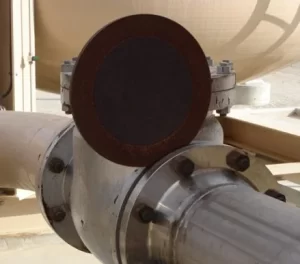

- Flanges

Pipe flanges are another critical component of your overall piping setup. Slip-ons, blinds, lap joints, threaded, and semis are among the many styles available. To ensure dependability, these pipe flanges are made of durable and sturdy materials. They also make pipe flanges from high-quality materials.

- Spectacle Blinds

People will usually use spectacle blinds, spades, and spacers for temporary or long-term solutions that is allowed for the isolation of piping sections. If a piece of machinery or a section of piping needs to be inspected, spectacle blinds will be used to isolate a specific section of the piping. They will also maintain the overall system during the process. It is recommended that you rigorously test the dependability of your spectacle blinds to stay safe because it is such an important role that is critical to your safety. Because each case is different, it is advised that you consult with a professional before investing large sums of money in spectacle blinds.

Characteristics of Stainless Steel Pipe

- Corrosion Resistance

Almost all stainless steel pipes on the market are iron-based alloys with at least 10.5 percent chromium content. When chromium is present in an alloy, it forms a self-healing or protective oxide layer. Furthermore, the formation of an oxide layer contributes to the corrosion resistance of stainless steel pipes. Intact corrosion resistance can be achieved regardless of fabrication method due to the self-healing properties of the oxide layer. Even if the stainless steel pipe surface is damaged or cut, it can self-heal and has a high corrosion resistance.

Work Intensification

One of the most significant benefits of work hardening stainless steel pipe grades is that it significantly increases and improves metal strength while also assisting in cold working. Aside from that, the combination of annealing and cold working stages is simple to use in order to provide adequate strength to fabricated components. Besides that, stainless steel pipe can self-heal and has a high corrosion resistance even if the pipe surface is damaged or cut.

- Strength and Formability

The strength of stainless steel pipe varies according to grade. In comparison to mild strength, strength remains somewhat constant in soft conditions. Austenitic steel, which is softer, has a high elongation and ductility. As a result, after a lengthy series of semi-fabrication, it can be cold worked to produce a finished product. Furthermore, toughness and strength must be effectively combined to achieve the desired result.

Ferritic stainless steel pipes are also extremely ductile and strong. Following heat treatment produces hardness and high strength in martensitic steel pipes.

Ductility

The percent elongation is responsible for ductility when performing a tensile test. The elongation of austenitic stainless steel is very high. The elongation of austenitic stainless steel is very high. Due to its high work hardening and ductility rates, austenitic stainless steel can form and work in a variety of processes, including deep drawing.

High Strength

Stainless steel pipe has a higher tensile strength than mild steel. Duplex stainless steel is generally stronger than austenitic steel. As a result, martensitic and precipitation hardening grades have the highest tensile strength. Furthermore, these grade types are twice as strong as other grades.

Magnetic Response

Magnetic response generally attracts stainless steel. Austenitic grades are purely nonmagnetic, though cold working can induce it in a few austenitic grades. Non-magnetic grades, on the other hand, such as 316 and 310, can be cold worked.

Types of Industry where Stainless Steel Pipe is Used

i. Oil and Gas

Technology is critical in the oil and gas industries. As the depths at which we search for oil have increased, so has the demand for corrosion-resistant piping. Hence, there will be more strain putting on the duplex and super duplex stainless steel pipes that we use. Corrosive environments can be extremely harmful. Besides that, if the damage is not repaired, the pipes will easily burst, rendering them unusable for deeper depths. Therefore, it is critical to have strong pipes in the oil and gas industry.

ii. Nuclear Power

It is difficult to extract useful energy from atomic nuclei. Because of cooling requirements, the majority of today’s nuclear reactors are located near the coast. As a result, it will use much of the water to cool these reactors comes from the sea. And it must be corrosion resistant. Stainless steel pipe is critical in the nuclear power industry. This is because of its capable of resisting corrosion caused by seawater.

iii. LNG Liquefied natural gas (LNG) is natural gas that has been cooled to -260 degrees Fahrenheit. So, it can be safely transported to meet the growing demand for natural gas. Also, natural gas is not always feasible or cost-effective to transport via pipelines. So, it is instead transported in liquid form via cryogenic sea vessels and road tankers. As a result, having the proper piping in place to provide safe and cost-effective LNG transport to hard-to-reach areas of the country or the world is critical.

Benefits of Stainless Steel Pipe

Stainless steel is a highly adaptable material that can be used in a variety of indoor and outdoor applications. Using stainless steel pipe for your project has several benefits, including:

- Lightweight

- Durable

- Long-lasting Capable of handling high flow rates

- Simple to machine

- Scratch resistance

- Simple to clean

- Low-maintenance

- Outstanding corrosion resistance

- Recyclable and eco-friendly material

Product Tags

Welded Line Pipe | |

Thickness | 1/8" (6mm), 1/4" (8mm), 3/8" (10mm), 1/2" (15mm), 3/4" (20mm), 1" (25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm) |

Standard | API 5L, ASME/ANSI B36.10 |

NDT | API 5L Annex E (as per client requirement) |

Heat Treatment | As per request |

Coating | Internal and external coating available as per request |

Specification | |

Carbon Steel | API 5L Gr.B |

High Yield Carbon Steel | API 5L X42/ 46/ 52/ 60/ 65/ 70 - PSL1/2 |

Low Temp Carbon Steel | ASME/ASTM SA/A671 CC65 CL22 |

Stainless Steel | ASME/ASTM SA/A312 304/304L, 316/316L, 317/317L,321/321H,310 |

Duplex / Super Duplex | UNS S31803, S32205, S32750, S32760, S31254 |

Size Range | |

ERW | 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm) |

LSAW | 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28 (700mm)", 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 38" (950mm), 40" (1000mm), 42" (1050mm), 44" (1100mm), 46" (1150mm), 48" (1200mm), 50" (1250mm), 52" (1300mm), 54" (1350mm), 56" (1400mm), 58" (1450mm), 60" (1500mm) |

Seamless Pipe | |

Size Range | 1/4" (8mm), 3/8" (10mm), 1/2" (15mm), 3/4" (20mm), 1" (25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28 (700mm)", 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 38" (950mm), 40" (1000mm), 42" (1050mm), 44" (1100mm), 46" (1150mm), 48" (1200mm) |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS, SCH 10s, SCH 40s, SCH 80s |

Standard | ASME/ANSI B36.10, B36.19 |

Specification | |

Carbon Steel | ASME/ASTM SA/A106 Gr A/ Gr B/ Gr C |

High Yield Carbon Steel | API 5L X42/ 46/ 52/ 60/ 65/ 70 - PSL1/ 2 |

Low Temp Carbon Steel | ASME/ASTM SA/A333 Grade 6 |

Chrome Moly | ASME/ASTM SA/A 335 Grade P5/ P11/ P22/ P91 |

Stainless Steel | ASME/ ASTM SA/A312 TP304/304L, 316/316L, 309, 309H, 310S, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | ASME/ASTM SA/A790 UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB163, 168, 424, 443, 575 UNS N02200 (Nickel 200), UNS N02201 (Nickle 201) UNS N04400 (Monel 400), UNS N06600 (Inconel 600) UNS N06601 (Inconel 601), UNS N06625 (Inconel 625) UNS N08810 (Incoloy 800H), UNS N08811 (Incoloy 800HT) |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK available |

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!