Butt Weld Fittings

Saliran Group is one of Pipe Fitting Supplier in Malaysia, Saliran Group has over 10 years of expertise in the trading and supply of high-quality butt weld fittings with numerous happy customers all around the world. We are the leading Pipe Fitting Supplier Malaysia that supply a variety of flange types such as 45, 90 & 180 degrees elbow, long, short radius & 3D elbow reducer, concentric & Eccentric reducer, equal & reducing tee, and end cap.

What are Butt Weld Fittings ?

A Pipe Fitting Malaysia is a component that functions as changing flow direction, branching, changing pipe diameter, or attaching off-line equipment in a piping system. These butt weld fittings are usually made by a seamless pipes or welded pipes via various processes, resulting in different shapes and angles such as elbows, tee, and reducer. Butt Weld Fittings Malaysia are customized to meet an extensive range of application requirements such as material grades and pressure.

Types of Butt Weld Fittings Types | ||

Type | Elbow Fittings | Long, Short Radius, 3D |

45 Degrees, 90 Degress & 180 Degrees | ||

Reducer Fittings | Concentric & Eccentric | |

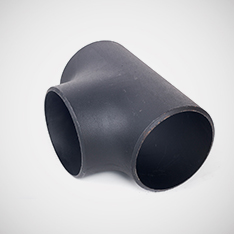

Tee Fittings | Equal & Reducing | |

End Cap Fittings | - | |

Size Range | 1/2" (15mm), 3/4" (20mm), 1"(25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5"(125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28" (700mm), 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 48" (1200mm) | |

Wall Thickness | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS SCH 10s, SCH 40s, SCH 80s | |

Standard | ASME B16.9, ASME B16.28, MSS SP-75 | |

Specification | |

Carbon Steel | ASME/ASTM SA/A234-WPB, WPC |

High Yield Carbon Steel | ASTM A860 WPHY 42/ 46/ 52/ 60/ 65/ 70 |

Low Temp Carbon Steel | ASME/ASTM SA/A420 WPL6 |

Chrome Moly | ASME/ASTM SA/A234-WP5, WP9, WP11, WP12, WP22, WP91 |

Stainless Steel | ASME/ASTM SA/A403WP 304/304L, 316/316L, 309, 304H, 310S, 317, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | ASME/ASTM SA/A815 |

Nickel Alloy | ASME/ASTM SB366, |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK available |

Definition of Fittings

Fittings are used to join straight pipe sections, adapt to various sizes or forms, and serve other functions including controlling (or monitoring) fluid flow. These fittings are used in the oil and gas industry to modify pipelines. Fittings are an essential component of plumbing and must be installed, which costs money, labour, materials, and tools. Technically speaking, valves are categorized part of fittings, but they are typically treated individually.

Type of Pipe Fittings

Pipe fittings seem to be the piping parts that support branch connections, size modifications, and directional changes in piping system. Pipe fittings such as pipe elbows fittings, reducers fittings, tee fittings, caps fittings, and crosses fittings, are frequently utilized in the oil & gas industries. Yet, it does not constitute pipe fittings when a piping system is bent to change direction. The pipe and the pipe fittings are always distinct components.

What is the Difference Between Stainless Steel Fittings & Carbon Steel Fittings?

Numerous fittings come in a variety of materials, however the key distinction of carbon steel pipes and stainless steel pipes fittings would be the type of steel used, as stainless steel is an alloy steel.

Due to their varied compositions, carbon steel and stainless steel have various levels of refining ductility, whilst carbon steel comes in a variety of forms. Carbon steel rusts if it is not coated with anti-rust oil or painted, unlike Stainless Steel Pipe Fittings Malaysia. Larger final product sizes can be accommodated by carbon steel pipe fittings.

Components of stainless steel tube embedded with in chemical components of the pipe’s surfaces will last for a long period without rusting and are difficult to degrade. Pipe Fitting Malaysia that are being used could play a significant part in ensuring that stainless steel pipe fittings will not generate quality issues with the pipe and that their service life is prolonged. Distinct forms of stainless steel have different qualities in addition to having different sorts of components.

Points to consider while choosing the Pipe Fittings

Several factors should be considered when choosing pipe fitting in your fluid system.

- Compatibility

Evaluating the compatibility with the pipe size, material, and unique system needs is a must before Choosing a type of fitting installed into the system. Compatibility ensures proper fit, effective sealing and optimum flow throughout the system. This reduces the possibility of leakage, pressure loss, or performance difficulties. Taking the effort to pick compatible fittings ensures that your plumbing system runs smoothly and efficiently, offering peace of mind and preventing any difficulties down the road.

- Specific Application

It is important to evaluate the types and configuration of fittings that suit your specific application. Such as the pressure and temperature limitation of fittings must the piping system’s requirement to avoid potential leaks, or any other failure happen. Properly analyzing the quality and durability of accessories is necessary, considering these aspects will create a better reliability and performance of fluid systems.

- Conditions of Use

There are a lot of factors that need to be considered when choosing a pipe fitting such as the need for corrosion resistance, or the type of pipe fitting will withstand environmental conditions and convey fluids. To make sure the piping system is cost-effective and runs efficiently, the pipe fitting must be easy to install. The pipe fitting must be easy to inspect and replace when problems happen to ensure the long-term reliability and minimize downtime of the piping system.

- Environment and Safety

To ensure the safety and reliability of the piping system, the chosen type of pipe fitting must follow the instructions and environment of the piping system. The fittings had to comply with the appropriate quality, performance and safety standards. Compliance with industry standards is top priority to ensure that the piping system operates with enhanced efficiency, effectiveness, and safety.

Standard of Butt-Weld Fittings in Malaysia

The standard of butt-weld fittings in Malaysia are followed by international standards such as ASME B16.9 (American Society of Mechanical Engineers) and MSS SP-75 (Manufacturers Standardization Society of the Valve and Fittings Industry). These standards specify the dimensions, materials, tolerances, and testing requirements for butt-weld fittings.

The materials commonly used for butt-weld fittings in Malaysia include:

- carbon steel ( ASTM A234-WPB)

- high-yield carbon steel (ASTM A860 WPHY)

- low-temperature carbon steel (ASTM A420 WPL6)

- chrome moly (ASTM A234-WP5, WP9, WP11, WP12, WP22, WP91)

- stainless steel (ASTM A403 WP304/304L, 316/316L, 309, 310S, 317, 321, 321H, 347, 347H, 904L)

- duplex/super duplex (UNS S31803, S32205, S32750, S32760)

- nickel alloys (such as Monel, Inconel, Incoloy, Hastelloy).

It is important to consult the specific standards and codes applicable to the project or industry to ensure compliance with the required standards for butt-weld fittings in Malaysia

Elaborate elbows fitting, reducer fitting, tee fittings, caps fitting and cross fittings

Elbows fittings are used to change the direction of a pipeline, available in different angles and radius types (short or long). Reducer fittings connect pipes of different diameters, either concentrically or eccentrically, ensuring smooth flow transition. Tee fittings create branch connections in pipelines, available in equal or reducing configurations, allowing for distribution or diversion of flow. Caps fittings seal the end of a pipe, providing closure and preventing fluid or gas flow. Cross fittings have four openings at right angles, enabling the connection of four pipes in a cross configuration, ideal for branching or intersecting pipelines. Careful selection ensures these fittings meet specifications and standards for proper function in various industries.

Click here to know more about our Butt Weld Fittings.