Gasket

What is Gasket?

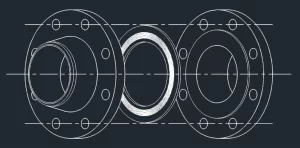

Flange gasket is intended to close the gap between two pipe sections. Gasket is also commonly referred to as an O-ring or washer. These objects often come in a variety of sizes and forms based on their intended use. Of course, flanged surfaces are used to join the majority of pipes. The joint between two pipes is not level or completely smooth. Instead, it has a flange, which flares out. Flange gasket is used for flanged surfaces like this one.

How Flange Gasket Works?

Like the majority of other gaskets, flange gasket functions similarly. They produce a sealed mating surface when installed, preventing leakage of water or other liquids. Water or other liquids usually flow through pipes. Water or other liquids may seep out through this mating surface if two pipes are linked together. Flange gaskets seal the surface to stop this from happening.

When used alone, pipes typically do not provide a sealed mating surface. This is particularly valid for pipes with flanged surface. This is particularly valid for pipes with flanged surfaces. Water and liquids can easily escape through the fractures on flanged surfaces because they are flared. Installing a flanged gasket is an easy way to stop leaks. To ensure that water or other liquids stay inside the pipes. The bordered gasket will adapt to the shape of the flanged surface.

Type of gasket flange

Non-metallic, semi-metallic, and metal gaskets are the three main types of flange gaskets.

In low pressure, low temperature, and noncritical service applications, non-metallic flange gaskets are employed. To fit in the grooves of the flange face, these flange gaskets are constructed from a soft substance.

Based on the needs of the Product and Service, the Semi Metallic Flange Gasket or Composite Flange Gasket is a blend of metal and nonmetal components. The Spiral wound Flange Gasket, which is appropriate for a wide variety of temperature and pressure Classes, is the most commonly used. A metal outer ring is typically fashioned into a spiral winding with a filler of graphite or PTFE, along with stainless steel or another alloy, to seal the flanged connection when squeezed.

The Metal Flange Gasket, also known as the Ring Type Joint Flange Gasket, is an all-metal gasket used to seal joints made of carbon steel, stainless steel, or other exotic alloys. The RTJ Flange Gaskets are intended for use in demanding situations involving high pressure and high temperature. A rectangular or oval cut groove on the face of the mated flanges receives the RTJ Flange Gasket. These flange gaskets are pressed into the grooves when they are tightened, creating a reliable seal at the flanged connection.

Properties of a Gasket

The gasket material ought to be highly tensile, flexible, and low in density. Additionally, it should be durable and resistant to internal pressure and chemicals. Additionally, it must adhere well to both itself and whatever else it touches.

The appropriate gasket will prevent corrosion in addition to sealing. Consideration must be given to additional abrasion, vibration, impact, and temperature fluctuations.

Nevertheless, strength is the most crucial component in every gasket application. It must be strong enough to sustain pressure without breaking under typical circumstances. This is done so that it can perform its main duty of sealing tightly.

Applications of a Gasket

There are various industrial applications for gaskets. Petrochemical, gas, machinery, and plumbing are some of the examples. In the workplace, gaskets in pumps, pipes, valves, and machinery are a few examples. The simplest approach to condense these is to consider the statement, “If it needs sealing and it does not move, it probably uses a gasket.”

Most people typically associate head gaskets with the metal or stainless steel gaskets used in automobiles. However, as you can see, there are many different types of gaskets.

Most frequently, they are passed off as something else, such as washers or O-rings. They all perform important tasks in a variety of applications.

How are Gaskets Tested?

Gasket goes through testing including hot compression tests as part of the evaluation procedure. This test establishes the maximum heat that the gasket can endure without material degradation or failure.

The next step is to inspect the sealant for any leaks and to look any other issues, such as pinholes or cracks. Before the product leaves the factory, professionals will undertake a thorough evaluation of it as the last step in the manufacturing process.

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!