Carbon steel pipe is made of carbon steel which is an iron and carbon steel alloy that considered as a tough material. Carbon steel pipe is also the most widely used pipeline material for construction, structural, and liquid transmissions for water, oil, and gas. Hence, it is utilised in a wide range of heavy-duty industries. This including infrastructure, ships, distilleries, and chemical fertiliser equipment because of its strength and capacity to endure stress. Therefore, it must withstand the application’s pressure, temperature, and corrosion conditions. Furthermore, these requirements are met by using pipe manufactured in accordance with an ASTM or API standard. The standard grades of carbon steel pipe include API 5L Grade B, X42 to X70, ASTM A106 B, ASTM A53 B, ASTM A252 Grade 3, and ASTM A333 Grade 6, among others.

Applications

Carbon steel pipes find numerous applications across various industries due to their strength, durability, and versatility. Here are some common applications:

Oil and Gas Industry: Carbon steel pipes are widely used in the oil and gas industry for transporting crude oil, natural gas, and petroleum products. They are preferred due to their ability to withstand high pressure and temperature conditions.

Water Transportation: Carbon steel pipes are extensively used for water transportation in municipal water supply systems, irrigation projects, and industrial water treatment plants. They offer corrosion resistance and can handle high flow rates.

Construction and Infrastructure: In construction projects, carbon steel pipes are used for structural support, piling, and underground utilities such as drainage systems and sewage lines. Their strength and durability make them suitable for heavy-duty applications.

HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems often utilize carbon steel pipes for distributing hot or cold water, steam, and air throughout buildings. These pipes offer thermal conductivity and are resistant to corrosion.

Industrial Applications: Carbon steel pipes are crucial in various industrial processes such as manufacturing, chemical processing, and power generation. They are used for conveying fluids, gases, and solids in piping systems within factories and plants.

Benefits

Safe & Long lasting

Carbon steel pipe is both safe and long-lasting. It is an ideal material for structural applications. It is because it is shock resistant and unaffected by harsh environmental conditions such as pressure or extreme weather.

Cost-effective

Because of carbon steel’s incredible strength, carbon steel pipe can be made thinner and with less material while still transporting large volumes. As a result, it is a cost-effective material.

Environmentally friendly

Furthermore, carbon steel is not only less expensive, but it is also recyclable. Hence, it is environmentally friendly and cost-effective.

Flexibility

Moreover, it is a versatile material because it is simple to manufacture. Therefore, it can be made in various thicknesses and sizes. Also, It is simple to cut and bend to fit wherever it is required.

Grade of steel used

Carbon steel pipe comes in a variety of grades and strengths, as well as wall thicknesses. As we have seen, the allowable stress is used to determine the required wall thickness. Hence, the allowable stress is determined by both the material’s metallurgy and the manufacturing method.

ASTM & API

Other than that, the various ASTM and API piping specifications provide guidelines for both metallurgy and manufacturing method. For example, ASTM Specifications A-53 and A-106, as well as API Standard 5L, are the most widely used piping specifications for process lines.

Schedules

Also, the primary wall thicknesses used are defined by schedules, such as Schedule 40, and weights, such as STD. In Grades A and B, ASTM A53 and ASTM A106 pipe are fabricated SMLS or seamed by electric resistance welding. However, tensile strength is higher in grades B. Besides that, ASTM A106 is available in three grades, A, B, and C, in descending order of tensile strength.

Manufacturing Methods

There are numerous methods for producing carbon steel pipes, and each one results in a pipe with a unique set of properties. Strength, wall thickness, corrosion resistance, and restrictions on temperature and pressure are a few of these qualities. For instance, pipes with the same wall thickness but different manufacturing processes may have varying strengths and pressure limits.

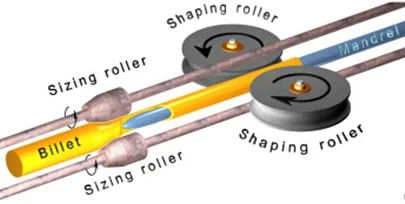

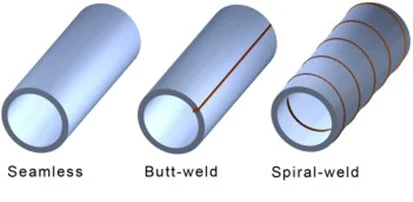

Seamless pipe is created by piercing a solid, near-molten steel rod, known as a billet, with a mandrel, resulting in a pipe with no seams or joints. Figure 1.0 depicts the manufacturing process of seamless pipe.

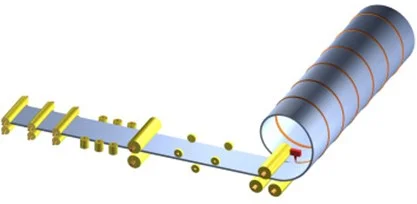

Butt-welded pipe is made by passing hot steel plate through shapers, which roll it into a hollow circular shape. Forcing the two ends of the plate together will result in a fused joint or seam. Figure 2.0 shows the steel plate as it begins the process of forming a butt-welded pipe.

Spiral-welded pipe is the least common of the three methods. The spiral-welded pipe is made by twisting metal strips into a spiral shape, similar to a barber’s pole, and then welding the edges together to form a seam. Because of its thin walls, this type of pipe is limited to low-pressure piping systems. Figure 3.0 depicts spiral-welded pipe prior to welding.

Lastly, the figure below shows the three previously described pipes in their final configuration.

Product Tags

Welded Line Pipe | |

Thickness | 1/8" (6mm), 1/4" (8mm), 3/8" (10mm), 1/2" (15mm), 3/4" (20mm), 1" (25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm) |

Standard | API 5L, ASME/ANSI B36.10 |

NDT | API 5L Annex E (as per client requirement) |

Heat Treatment | As per request |

Coating | Internal and external coating available as per request |

Specification | |

Carbon Steel | API 5L Gr.B |

High Yield Carbon Steel | API 5L X42/ 46/ 52/ 60/ 65/ 70 - PSL1/2 |

Low Temp Carbon Steel | ASME/ASTM SA/A671 CC65 CL22 |

Stainless Steel | ASME/ASTM SA/A312 304/304L, 316/316L, 317/317L,321/321H,310 |

Duplex / Super Duplex | UNS S31803, S32205, S32750, S32760, S31254 |

Size Range | |

ERW | 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm) |

LSAW | 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28 (700mm)", 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 38" (950mm), 40" (1000mm), 42" (1050mm), 44" (1100mm), 46" (1150mm), 48" (1200mm), 50" (1250mm), 52" (1300mm), 54" (1350mm), 56" (1400mm), 58" (1450mm), 60" (1500mm) |

Seamless Pipe | |

Size Range | 1/4" (8mm), 3/8" (10mm), 1/2" (15mm), 3/4" (20mm), 1" (25mm), 1-1/4" (32mm), 1-1/2" (40mm), 2" (50mm), 2-1/2" (65mm), 3" (80mm), 3-1/2" (90mm), 4" (100mm), 5" (125mm), 6" (150mm), 8" (200mm), 10" (250mm), 12" (300mm), 14" (350mm), 16" (400mm), 18" (450mm), 20" (500mm), 22" (550mm), 24" (600mm), 26" (650mm), 28 (700mm)", 30" (750mm), 32" (800mm), 34" (850mm), 36" (900mm), 38" (950mm), 40" (1000mm), 42" (1050mm), 44" (1100mm), 46" (1150mm), 48" (1200mm) |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS, SCH 10s, SCH 40s, SCH 80s |

Standard | ASME/ANSI B36.10, B36.19 |

Specification | |

Carbon Steel | ASME/ASTM SA/A106 Gr A/ Gr B/ Gr C |

High Yield Carbon Steel | API 5L X42/ 46/ 52/ 60/ 65/ 70 - PSL1/ 2 |

Low Temp Carbon Steel | ASME/ASTM SA/A333 Grade 6 |

Chrome Moly | ASME/ASTM SA/A 335 Grade P5/ P11/ P22/ P91 |

Stainless Steel | ASME/ ASTM SA/A312 TP304/304L, 316/316L, 309, 309H, 310S, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | ASME/ASTM SA/A790 UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB163, 168, 424, 443, 575 UNS N02200 (Nickel 200), UNS N02201 (Nickle 201) UNS N04400 (Monel 400), UNS N06600 (Inconel 600) UNS N06601 (Inconel 601), UNS N06625 (Inconel 625) UNS N08810 (Incoloy 800H), UNS N08811 (Incoloy 800HT) |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK available |

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!