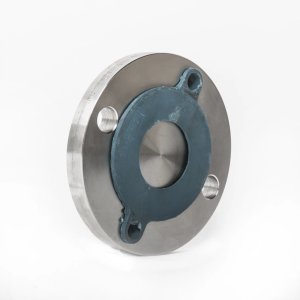

A blind flange is also known as a solid flange. Blind flange is primarily designed to cap off a line. It is also designed to cover a pipe or nozzle on a vessel that is not being utilised. In addition, a nozzle is normally a pipe that exits a container which is flanged. By that, it can be attached to valves or pipework. A nozzle is frequently blocked off from a blind flange for load tests in a plant or just because the customer doesn’t use all the nozzles that were provided on the tank. Other blind flanges are made of simple materials, need little machining in comparison to other flanges. Furthermore, blind flanges are weight more than most alternatives since they lack a bore. Other than that, we also offer custom machined parts to match up to slip-on and weld neck flanges. NPT threads in the middle and custom bore holes are common modifications. Blinds can also be provided with high hubs (most API 6BX blinds have high hubs as a requirement).

Where are Blind Flanges Most Commonly Used?

In general, the blind flange can have a raised face, a ring joint face, or a flat face. If it has a raised face, we would propose a standard ring gasket suitable for the servicing and/or test. The most common reason a flange may be flat faced is because it was not built to withstand the bending pressures that would come from using a ring gasket or raised face flange.

Also, the blind flange is being used to blank off the end of piping, valves, and pressure vessel openings, similar to a plug or cap. It can be made of cast iron, forgings, specific plates, or flat bars. Unlike a welded cap, the blind flange allows easy access to the inner of a vessel or pipe because it is bolted. Besides that, they are the most stressed of all standard flange types in addition to the internal pressure as well as bolt loading, especially in large sizes.

Benefits of choosing Blind Flanges

Blind flanges are crucial components in pipelines, offering several benefits:

Closure and Isolation: One of the primary functions of a blind flange is to seal off the end of a pipeline. This prevents the flow of fluids or gases through that particular section, allowing for maintenance, repairs, or inspections to be carried out downstream without affecting other parts of the pipeline.

Safety: By providing a secure closure, blind flanges enhance safety by minimizing the risk of leaks, spills, or accidents during maintenance activities or shutdowns. This is particularly important in industries dealing with hazardous materials or volatile substances.

Pressure Testing: Blind flanges are often used during pressure testing of pipelines. By closing off the end of the pipeline with a blind flange, pressure can be applied to the system to check for any leaks or weaknesses in the piping infrastructure before it is put into service.

Temporary Blockage: In situations where a section of the pipeline needs to be temporarily blocked off, such as for maintenance work or equipment installation, blind flanges can be quickly installed and removed as needed, providing a temporary blockage solution without the need for permanent modifications to the pipeline.

Flexibility and Versatility: Blind flanges come in various sizes, materials, and pressure ratings, making them versatile components suitable for a wide range of pipeline applications. They can be customized to meet specific project requirements, ensuring compatibility with different pipeline systems.

Corrosion Resistance: Depending on the material chosen for construction, blind flanges can offer excellent corrosion resistance, prolonging the service life of the pipeline and minimizing the need for frequent replacements or repairs.

Cost-Effectiveness: Compared to other closure methods, such as welding caps or plugs, blind flanges offer a cost-effective solution for pipeline closure and isolation. They can be easily installed and removed without requiring specialized equipment or labor-intensive procedures, reducing downtime and associated costs.

Standardization: Blind flanges are manufactured according to industry standards such as ASME B16.5 or API 605, ensuring compatibility and interchangeability with other pipeline components. This standardization simplifies procurement, installation, and maintenance processes, streamlining operations for pipeline operators.

In summary, blind flanges play a vital role in pipeline systems by providing secure closure, facilitating maintenance activities, ensuring safety, and offering versatility and cost-effectiveness across various industrial applications.

Product Tags

Type | Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange, Anchor Flange, Orifice Flange |

Size Range | 1/2" (15mm) - 48" (1200mm) |

Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

Type Available | Raised Face RF, Ring Type Joint RTJ, Flat Face FF, Male & Female M&F, Tongue Groove T&G |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS SCH 10s, SCH 40s, SCH 80s |

Standard | ASME B16.1, ASME B16.5, ASME B16.20, ASME B16.21, ASME B16.24, ASME B16.34, ASME B16.36, ASME B16.42, ASME B16.47 MSS SP-6, MSS SP-9, MSS SP-25, MSS SP-44, MSS SP-53, MSS SP-54, MSS SP-55, MSS SP-75, MSS SP-106 API 605, API 6A, API 6B |

Specification | |

Carbon Steel | ASME/ASTM SA/A105N |

High Yield Carbon Steel | ASTM A694 F42/ 46/ 52/ 60/ 65/ 70 ASTM A707 L1~ L8 |

Low Temp Carbon Steel | ASME/ASTM SA/A350 LF1/ 2/ 3/ 6 |

Chrome Moly | ASME/ASTM SA/A182F2, F5 ,F9, F11, F12, F22, F91 |

Stainless Steel | ASME/ASTM SA/A182F304/304L, 316/316L, 309, 310, 304H, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB564, |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK, Weld Overlay available |

flanges supplier malaysia

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!