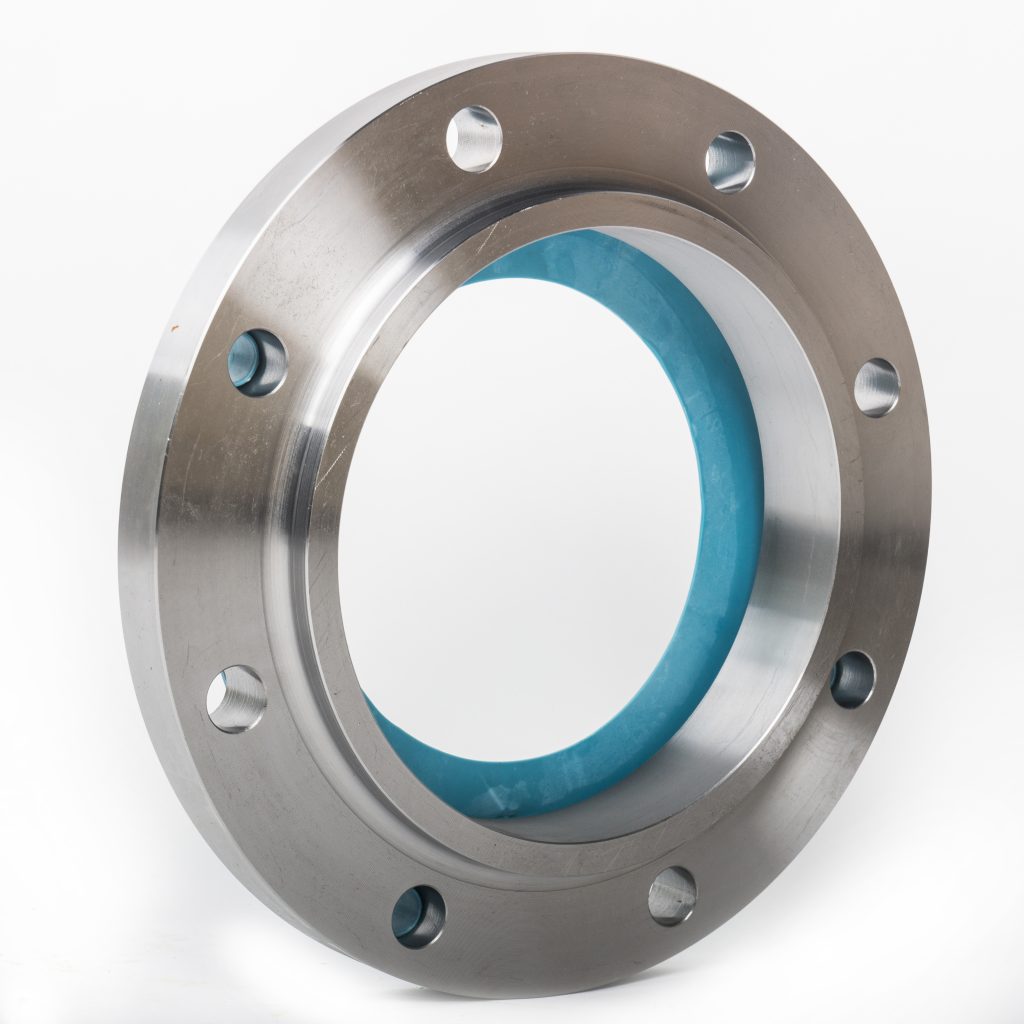

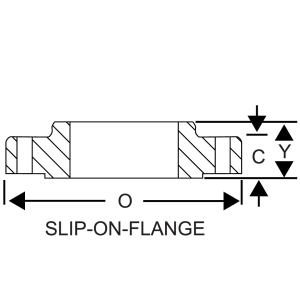

Slip on flange are also known as SO flange. It is widely known due to its low material cost and ease of installation. There are many different diameters as well as low-pressure models to choose between. Slip on flange, apart from welding neck flanges, lacks a neck to rest on the pipe, necessitating double welding. A slip-on flange is a type of flange that is designed to slip over the end of a pipe and then be welded in place. It has a slightly larger inside diameter than the outside diameter of the pipe it is intended to be used with. This allows the flange to slide over the pipe, and then the pipe and flange are welded together.

How Does A Slip On Flange Work?

Slip on flange are designed to fit over pipes and are slightly larger inside than pipe. They connect to the pipe via a fillet weld at the top and bottom of the flange. In addition, it is used to insert the pipe into the flange’s inner hole. It is because the flange’s inner diameter is slightly larger than the pipe’s outer diameter. Hence, the pipe and flange can be joined by lap welding at the top and bottom of the flange.

Accordingly, it lacks a weld bevel, hence it is a simple and excellent alternative to a weld neck, allowing the pipe to be adjusted in length relative to the flange’s position. Other than that, the flange’s bore will provide plenty of room for the matching pipe. By that, it provides enough working space for the welder and fabricator to connect.

Besides that, it is very common in low-pressure applications. Most of the flanges would have a hub that looks dimensionally similar to a raised face. If space is tight and also the application enables for a “ring style” slip on, it could be furnished without a hub. Even though the hub style seems to be more usual when referring to a slip on, a ring style slip on without a hub is still considered a slip on flange. In order to have a better connection, the flanges in higher pressure classes are frequently made with the height of a lap joint.

Types of Slip On Flanges

While slip-on flanges primarily serve the function of connecting pipes in a piping system, they come in various types to suit different needs and applications. Here are some common types of slip-on flanges:

- Raised Face Slip-On Flange: This type of slip-on flange has a raised face around the bore hole, which serves as a mating surface for the gasket. The raised face helps create a tighter seal between the flange and the mating component, reducing the risk of leaks.

- Flat Face Slip-On Flange: Unlike the raised face flange, a flat face slip-on flange has a flat surface without any raised area around the bore hole. It requires the use of a flat gasket and is typically used in applications where a raised face is not necessary or desired.

- Ring Type Joint (RTJ) Slip-On Flange: RTJ slip-on flanges feature a groove machined into the flange face to accommodate a metal ring gasket. These flanges are commonly used in high-pressure and high-temperature applications where a reliable and leak-proof seal is required.

- Male and Female Slip-On Flange: In this type, one flange has a raised face while the mating flange has a corresponding depression or female face. The raised face fits into the depression, providing a more secure fit and alignment between the flanges

Product Tags

Type | Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange, Anchor Flange, Orifice Flange |

Size Range | 1/2" (15mm) - 48" (1200mm) |

Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

Type Available | Raised Face RF, Ring Type Joint RTJ, Flat Face FF, Male & Female M&F, Tongue Groove T&G |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS SCH 10s, SCH 40s, SCH 80s |

Standard | ASME B16.1, ASME B16.5, ASME B16.20, ASME B16.21, ASME B16.24, ASME B16.34, ASME B16.36, ASME B16.42, ASME B16.47 MSS SP-6, MSS SP-9, MSS SP-25, MSS SP-44, MSS SP-53, MSS SP-54, MSS SP-55, MSS SP-75, MSS SP-106 API 605, API 6A, API 6B |

Specification | |

Carbon Steel | ASME/ASTM SA/A105N |

High Yield Carbon Steel | ASTM A694 F42/ 46/ 52/ 60/ 65/ 70 ASTM A707 L1~ L8 |

Low Temp Carbon Steel | ASME/ASTM SA/A350 LF1/ 2/ 3/ 6 |

Chrome Moly | ASME/ASTM SA/A182F2, F5 ,F9, F11, F12, F22, F91 |

Stainless Steel | ASME/ASTM SA/A182F304/304L, 316/316L, 309, 310, 304H, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB564, |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK, Weld Overlay available |

flanges supplier malaysia

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!