Weld neck flange is also known as a tapered hub flange or high-hub flange. Weld neck flange is a type of flange that can relocate stress to the pipes, resulting in a reduction in high-stress concentration at the flange’s bottom. There are two types of welding neck flanges: the first is used with wipes, while the second, longer type is used with process plants rather than pipes. Moreover, it is made up of a round fitting that extends beyond the circumference’s rim which allow the flanged to be attached to a bolted flange. Because of the structural valve, this design is far superior. And the flanges are easily identified by the long-tapered hub that gradually extends over to the wall thickness of a pipe or fitting.

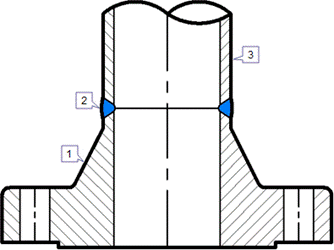

Product Structure

Weld Neck Flanges are flanges that are designed to be buttwelded to a piping system. This type of flange includes numerous specifications. Besides that, the long-tapered hub serves as an important reinforcement in a variety of applications involving high pressure, sub-zero, and/or elevated temperatures. Also, under conditions of repeated bending caused by line expansion or other variable forces, the smooth transition from flange thickness to pipe or fitting wall thickness effected by the taper is extremely beneficial.

It is also more expensive due to its long neck and the cost of people to connect the flange to the pipeline or fitting. However, it is preferred for high-stress applications. Moreover, the stresses are transmitted to the pipeline via the necks, or hubs. Furthermore, the gradual transition of thickness from the base of the hub to the wall thickness at the butt weld reinforces the flange.

Type of Weld Neck Flange

Weld neck flanges come in two shapes: one with a reducing neck, known as reducing weld neck flange, and one with an even diameter of a typical long neck, known as long neck weld flange.

i. Reducing Weld Neck Flange

As the name implies, it is a combination of a pipe reducer and a flange that can be welded directly to a smaller pipe.

ii. Long Weld Neck Flange

Long weld neck flanges are commonly found on vessel nozzles and equipment. Moreover, the flanges are made to fit the inside diameter of the pipe or fitting. Also, it is bored to match because it reduces the corrosion and turbulence that occurs inside the pipe.

Application of Weld Neck Flange

Welded neck flanges have a long-tapered hub and are frequently used in high-pressure applications. It is critical to specify the schedule pipe used when ordering a flange. This is due to the inside diameter of flange matching the inside diameter of your pipe. This flange’s buttweld joint with the pipe, combined with the tapered hub, makes it very resistant to dishing and a very sturdy connection. These flanges are ideal for extreme temperature fluctuations and environments where the flanges will be bent and handled frequently.

Advantages

Weld neck flanges are appropriate for use in hostile environments with temperature, pressure, or other sources of stress. Also, this type of flange achieves resilience by sharing environmental stress with the pipe to which it is welded. Other than that, this flange has been used successfully at pressures as high as 5,000 psi.

On the other hand, its name from the flange’s neck, which is welded to the end of a piping system. Hence, it is intended to transfer stress to the pipe, reducing high stress concentrations at the flange’s base. By that, it is more expensive due to their design and engineering, as well as the increased material.

Product Tags

Type | Blind Flange, Slip on Flange, Welding Neck Flange, Socket Weld Flange, Threaded Flange, Lap Joint Flange, Anchor Flange, Orifice Flange |

Size Range | 1/2" (15mm) - 48" (1200mm) |

Class | 150#, 300#, 600#, 900#, 1500#, 2500# |

Type Available | Raised Face RF, Ring Type Joint RTJ, Flat Face FF, Male & Female M&F, Tongue Groove T&G |

Schedule | SCH 10, SCH 20, SCH 30, SCH 40, SCH 60, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160 SCH STD, SCH XS, SCH XXS SCH 10s, SCH 40s, SCH 80s |

Standard | ASME B16.1, ASME B16.5, ASME B16.20, ASME B16.21, ASME B16.24, ASME B16.34, ASME B16.36, ASME B16.42, ASME B16.47 MSS SP-6, MSS SP-9, MSS SP-25, MSS SP-44, MSS SP-53, MSS SP-54, MSS SP-55, MSS SP-75, MSS SP-106 API 605, API 6A, API 6B |

Specification | |

Carbon Steel | ASME/ASTM SA/A105N |

High Yield Carbon Steel | ASTM A694 F42/ 46/ 52/ 60/ 65/ 70 ASTM A707 L1~ L8 |

Low Temp Carbon Steel | ASME/ASTM SA/A350 LF1/ 2/ 3/ 6 |

Chrome Moly | ASME/ASTM SA/A182F2, F5 ,F9, F11, F12, F22, F91 |

Stainless Steel | ASME/ASTM SA/A182F304/304L, 316/316L, 309, 310, 304H, 310H, 317/317L, 321, 321H, 347, 347H, 904L |

Duplex/ Super Duplex | UNS S31803, S32205, S32750, S32760 |

Nickel Alloy | ASME/ASTM SB564, |

Remark | HIC, PED 2014/68/EU, NACE MR0175, NORSOK, Weld Overlay available |

flanges supplier malaysia

Looking for flanges, fittings, pipes, valves and gasket?

Saliran Group has over 10 years of experiences in trading of a wide range of flanges, pipes, valves, fittings, gasket and related parts and accessories (“PVF products”) as well as steel products with numerous happy customers all around the world. We supply a variety of gaskets either in metal, non-metal as well as food-grade approval available material.

Click on the link below to contact us now!