Type of Instrument valve: Function and Basic

1. What is Instrument valve?

- Instrument measurement shows up in applications that require valves. These applications include static pressure, isolation, differential pressure, Venting, liquid level, gauge pressure and instrument lines. In addition, at the end connection of valves, female NPT & Male NPT can be found.

2. Different type of Instrument valve

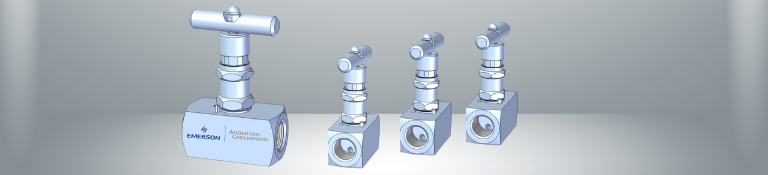

Hand Valve

The existing of hand valve control the amount of inlet steam nozzles to be used while operating. TESCOM Anderson Greenwood Instrumentation hand valves are suitable for all instrument isolation duties, helping provide bubble tight shut-off time after time. Also, with metal or soft seats for gas, vapor or liquid applications, rated up to 10,000 psig (690 barg), there is a hand valve for even the most severe service. It is available in standard or exotic materials.

Technical Data of TESCOM Anderson Greenwood Instrumentation

Features | Details |

|---|---|

Materials | CS, SS, Monel®, Hastelloy®, Duplex and other exotic materials |

Seat | Metal and Soft |

Connections | 1/4” to 1/2” threaded, flanged, also suitable for direct mounting |

Orifice sizes | 3.0 mm (0.12 in) , 4.7 mm (0.19 in) |

Pressure max | 6,000 psig (414 barg) |

Temperature max | 538 °C (1000 °F) |

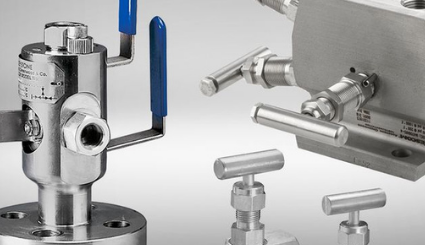

Gauge Valve

Typically, a gauge valve works as a single shutoff needle valve to isolate the gauge from the process. For example, TESCOM Anderson Greenwood Instrumentation gauge valves include multi-port and block and bleed styles suitable for gauge isolation, calibration, and venting with a choice of either a globe pattern or straight through bore design. Other than that, a wide choice of end connections and comprehensive range of standard gauge accessories allows complete flexibility for individual installations.

Technical Data of TESCOM Anderson Greenwood Instrumentation

Features | Details |

|---|---|

Materials | CS, SS, Monel®, Hastelloy®, Duplex and other exotic materials |

Seat | Metal and Soft |

Connections | 1/4” to 1/2” threaded, flanged, also suitable for direct mounting |

Orifice sizes | 3.0 mm (0.12 in) , 4.7 mm (0.19 in) |

Pressure max | 6,000 psig (414 barg) |

Temperature max | 538 °C (1000 °F) |

Manifold Pressure

Furthermore, pressure transmitter and differential pressure transmitter require valve manifolds as standard accessories. Thus, range of TESCOM Anderson Greenwood Instrumentation pressure manifolds is suitable for all types of static pressure instruments; from gauges to “smart” pressure transmitters. Other than that, it is available for direct or remote mounting, the pressure manifolds enable isolation, calibration, and venting in a single unit.

Technical Data of TESCOM Anderson Greenwood Instrumentation

Features | Details |

|---|---|

Materials | CS, SS, Monel®, Hastelloy®, Duplex and other exotic materials |

Seat | Metal and Soft |

Connections | 1/4” to 1/2” threaded, flanged, also suitable for direct mounting |

Orifice sizes | 3.0 mm (0.12 in) , 4.7 mm (0.19 in) |

Pressure max | 6,000 psig (414 barg) |

Temperature max | 538 °C (1000 °F) |

3. Choosing Right Instrument valve

Moreover, a number of fundamental factors need to be taken into account when choosing an instrumentation valve. Listed below are some of the main factors to consider.

- Basic Valve/Packing Designs

- Pressure and Temperature Considerations

- Pressure Fluctuation

Looking for Instrument Valve?

Send us your spec, our 10+ Years experienced sales team is ready to deliver your products.